What is the difference between a dual wall heat shrink tube and a single wall heat shrink tube?

Single wall heat shrink tube:The waterproof sleeve made of heat-shrinkable film raw materials is used to extrude the polymer or polymer aluminum alloy to obtain the tubular intermediate product of the required specifications. The tubular product of certain specifications obtained after radiation (or organic chemistry) chemical crosslinking is heated, expanded, cooled and shaped to become a heat-shrinkable band tube.

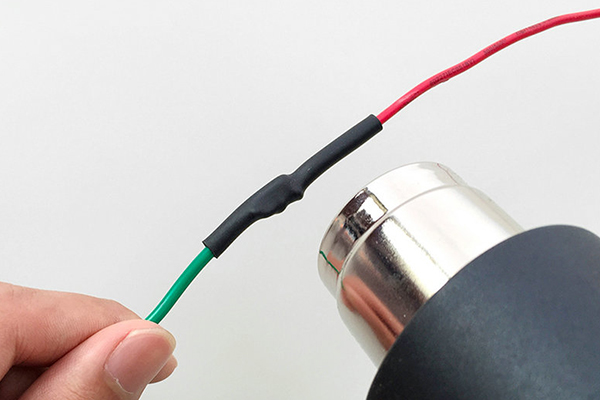

Dual wall heat shrink tube: Basically, a layer of hot melt glue is added to the ordinary heat shrink tube. In summary, the single wall is a general heat shrink tube, and the inner cavity is not coated with hot melt adhesive. The double-wall heat shrinkable tube is characterized in that the cavity of the heat shrinkable tube is coated with a layer of hot melt adhesive.

The inner cavity of the heat shrinkable double-wall heat shrinkable tube and the glue coated mid-wall tube can be coated. Naturally, many people can use a mid-wall thermoplastic tube without a coating.

Midwall coated heat shrinkable tube Radiation crosslinked heat shrinkable midwall thermoplastic tube is generally used for insulation safety protection of medium and low voltage power engineering products and moisture protection of communication equipment. The inner cavity of the product is coated with spiral hot melt adhesive, which has excellent direct coating performance and excellent sealing effect. MWP and MWPC are uncoated and coated products respectively. The double-wall adhesive heat shrinkable tube is a semi-soft heat shrinkable tube with a hot melt adhesive in the inner layer.

The surface layer is a radiation crosslinked polyolefin, and the inner layer is a gel chamber with professional design scheme. When heated, the inner cavity melts, the surface gathers and is filled with pores or gaps after cooling, the wall thickness of the heat-shrinkable double-wall heat-shrinkable tube is symmetric and firm.