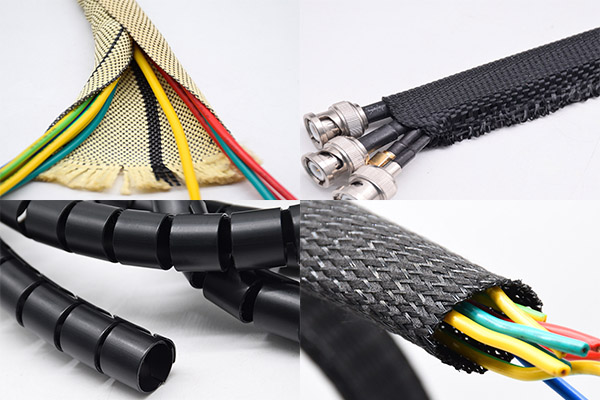

PET braided sleeving is widely used in various fields due to its excellent durability, flexibility and protective properties. Whether it is cable protection in industrial environments or cable management in home and office environments, PET braided sleeving provides the ideal solution. This article will explore the application of PET braided sleeving in different scenarios, demonstrating its versatility and practicality.

1. Home and Office

Cable management and organization:

In homes and offices, cluttered cables are not only aesthetically pleasing but can also pose safety hazards. PET braided sleeves can effectively organize and manage cables, neatly storing multiple cables together and keeping the environment tidy. Our newly launched cable management tube can be freely adjusted in length and can be used in lifting desks, etc. to manage wire harnesses.

2. Cars and ships

Cable protection:

In cars and ships, cables are subject to challenges such as high temperatures, moisture, vibration and mechanical wear. PET high flame retardant braided sleeving has good high temperature resistance and wear resistance, which can effectively protect the cable and extend its service life.

For example, PET braided sleeving can be used inside the engine compartment, dashboard and car body to ensure the safe operation of cables under harsh conditions.

Noise suppression:

Some PET braided sleevings have noise suppression functions, which can reduce friction noise between cables, like noise reduction braided sleeving improves the quietness of vehicles and ships, and provide a more comfortable ride experience.

3. Industrial automation

Machinery and equipment protection:

In the field of industrial automation, cables need to face complex working environments, including mechanical wear, chemical corrosion, high temperature and high pressure, etc. PET braided casing can provide comprehensive protection for cables and ensure stable operation of equipment.

For example, cable management in industrial robots, automated production lines and machine tool equipment can all use PET braided sleeves to prevent cable damage and failure.

4. Aerospace

Fireproof and high temperature resistant:

The aerospace field has extremely strict requirements on the fire resistance and high temperature resistance of cables. PET braided sleeving meets these high standards, providing excellent cable protection and ensuring flight safety.

For example, cables in aircraft electrical systems, control systems and communication systems can all use PET braided sleeves to prevent damage to the cables from fire and high temperature.

Conclusion

PET braided sleeves are widely used in homes, offices, automobiles, ships, industrial automation, aerospace, and data centers due to their versatility and excellent performance. Whether it is for cable management, aesthetics and tidiness, or for safety protection and equipment maintenance, PET braided sleeving is an ideal choice. Through the rational use of PET braided sleeving, the service life of the cable and the overall reliability of the system can be effectively improved, creating a safer, neater and more efficient working and living environment.