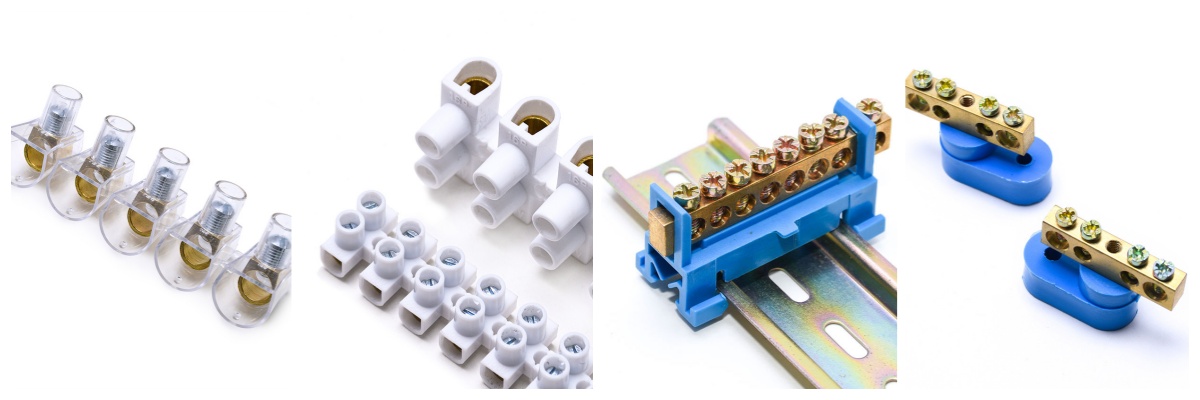

Distribution blocks and terminal blocks are both components used in electrical wiring systems, but they serve different purposes and are designed for distinct applications.

Purpose:

Distribution Block: The primary function of a distribution block is to distribute electrical power from a single source to multiple circuits. It typically has multiple output terminals that branch off from a single input terminal.

Terminal Block: Terminal blocks are used for connecting, organizing, and securing electrical wires or cables. They provide a convenient way to terminate wires and are often used for connecting multiple wires within a control panel or electrical enclosure.

Configuration:

Distribution Block: Distribution blocks usually have one input terminal for incoming power and multiple output terminals for distributing power to various circuits or loads.

Terminal Block: Terminal blocks can vary in configuration. They may have multiple connection points (terminals) for wires to be secured, and they can be arranged in various ways, such as in rows or in a modular fashion.

Number of Poles:

Distribution Block: Distribution blocks are often designed with multiple poles, with each pole representing a connection point for a circuit.

Terminal Block: Terminal blocks can be single-pole (one wire per connection point) or multi-pole, depending on the design and application.

Application:

Distribution Block: Distribution blocks are commonly used in power distribution panels, where a single power source needs to be distributed to multiple loads or circuits.

Terminal Block: Terminal blocks are widely used in control panels, electrical cabinets, and other applications where wires need to be terminated, connected, or organized within a confined space.

Voltage and Current Ratings:

Distribution Block: Distribution blocks are typically designed to handle higher voltage and current levels, suitable for power distribution applications.

Terminal Block: Terminal blocks may have different voltage and current ratings depending on their intended use. They are often used for low-voltage control and signal wiring.